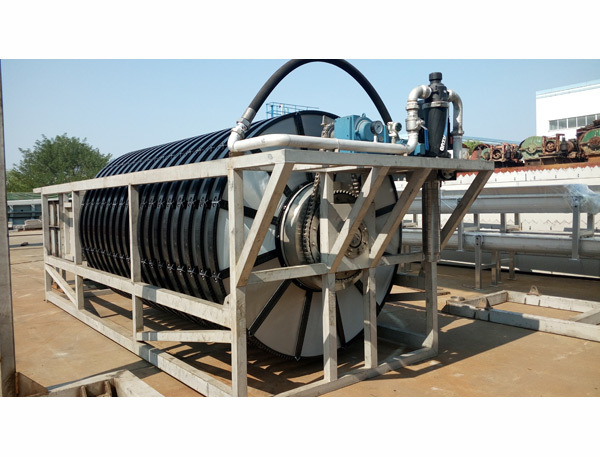

Fiber Disc Filter

Keywords: pretreatment equipment, aeration equipment

Product Description

Fiber Disc Filter

This equipment is widely used in various wastewater treatment plants to upgrade the effluent water quality from Class B to Class A, reducing the suspended solids content from 20mg/L to below 10mg/L, and total phosphorus from 1mg/L to below 0.5mg/L, fully meeting national emission standards.

Features

(1) Good and stable effluent water quality.

(2) Novel design, impact load resistant.

(3) Simple and compact equipment, few auxiliary equipment, low investment in the entire filtration system.

(4) Low equipment idle rate, low total installed power.

(5) Automated operation, therefore simple and convenient operation and maintenance.

(6) Much smaller head loss than sand filters.

(7) Much smaller footprint than other filter pools.

(8) Fabric disc filters are easier to install than granular filters.

(9) Short design and construction cycle.

(10) Low requirements for ground bearing capacity, low investment in equipment foundation. Especially suitable for upgrading and renovating existing wastewater treatment plants, enabling effluent to reach Class A from Class B.

Working Principle:

Raw water enters the filter pool, after energy dissipation by the baffle, it passes through the microporous filter cloth fixed on the support. Solid suspended matter is retained on the outside of the filter cloth, and the filtrate is collected through the hollow pipe and discharged from the filter pool by gravity flow through the overflow weir. During filtration, sludge adheres to the outside of the filter cloth, gradually forming a sludge layer. As the sludge accumulates on the filter cloth, the filtration resistance of the filter cloth increases, and the liquid level in the pool gradually rises. When the liquid level rises to the set value, the PLC simultaneously starts the back suction pump and the transmission device. During the rotation of the disc, the scraper fixed to the outside of the filter cloth rubs against the surface of the filter cloth, scraping off the sludge on the surface of the filter cloth. At the same time, the water inside the disc is sucked from the inside to the outside, cleaning the sludge in the micropores of the filter cloth. A sludge discharge pipe is set at the bottom of the pool, and the sludge pump is automatically started by the PLC according to the time setting to discharge the sludge.

Operating Mode:

The operating states of the fiber disc filter include: static filtration process, negative pressure cleaning process, and sludge discharge process.

(1) Static filtration process: Wastewater flows into the filter pool by gravity, and the filter pool is equipped with baffle energy dissipation facilities. Wastewater is filtered through the filter cloth, and the filtrate is collected through the hollow pipe and discharged from the filter pool by gravity flow. The whole process is continuous.

(2) Negative pressure cleaning process: During filtration, some sludge adheres to the outside of the filter cloth, gradually forming a sludge layer. As the sludge accumulates on the filter cloth, the filtration resistance of the filter cloth increases, and the water level in the filter pool gradually rises. The water level height in the pool is detected by a pressure monitoring device. When the water level reaches the cleaning set value (high water level), the PLC starts the back suction pump and begins the cleaning process. During cleaning, the filter pool can continue to filter. During filtration, the filter disc is static, which is conducive to sludge sedimentation at the bottom of the pool. During cleaning, the filter disc rotates at 1 revolution/minute. The suction pump sucks the sludge particles accumulated on the filter cloth under negative pressure, and the water inside the filter disc is sucked at the same time, and the water cleans the filter cloth from the inside to the outside and discharges the cleaned water. The cleaning area only accounts for 1% of the total filter disc area. The cleaning process is intermittent.

(3) Sludge discharge process: The fiber disc filter has a hopper-shaped bottom under the filter disc, which is conducive to the collection of sludge at the bottom of the pool. The sludge sedimentation at the bottom of the pool reduces the amount of sludge on the filter cloth, which can prolong the filtration time and reduce the water consumption for cleaning. After a set time period, the PLC starts the sludge pump to discharge the sludge back to the wastewater pretreatment structure through the sludge discharge pipe at the bottom of the pool.

Product Consulting

We will contact you within one working day. Please pay attention to your email.