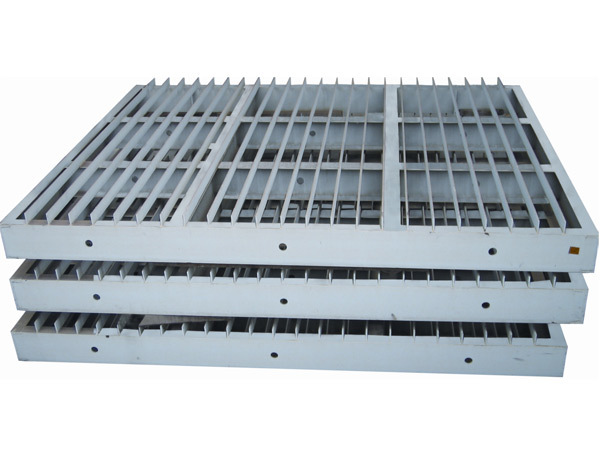

XPLS and XPLW type flat bar screens and grids

Keywords: pretreatment equipment, aeration equipment

Product Description

Generally located in front of the intake, this is a frame-type structure used to intercept debris such as aquatic plants and driftwood (generally called pollutants) carried by the water flow. The trash rack consists of a frame, baffles, and bars (working net), generally made of steel. The spacing between the bars depends on the size and quantity of pollutants and operational requirements. The spacing of the bars used in hydropower stations depends on the model and size of the water turbine, ensuring that pollutants passing through the trash rack will not get stuck in the water turbine's flow components. Trash racks are generally not installed in spillways and spill holes. If the diameter or aperture is small and there is a lot of driftwood requiring installation, the spacing of the bars (working net) should be increased. The load on the trash rack, in addition to its own weight, is mainly the water load formed by the water level difference before and after the rack due to blockage of pollutants, generally considered to be a 2-4m head. The size of the trash rack surface is determined by the flow rate through the rack and the allowable flow velocity through the rack. To reduce head loss and facilitate cleaning, the flow velocity through the rack is generally required to be no more than about 1.0 m/s. Trash racks can be made fixed or hoistable.

1. Main Structure

The flat bar screen mainly consists of a frame and bars, and a gate slot can also be provided as needed.

Frame

The frame is welded from steel sections. The frame structure ensures that the screen operates normally when the water level difference before and after is no more than 1m.

Bars (Working Net)

The water surface turning point of the bars is made into a circular arc streamline shape, with a smooth surface, which can smoothly intercept pollutants and is easy to clean, preventing floating objects in the water from adhering to the rough water-facing surface of the bars and becoming difficult to remove. The bars are firmly installed, evenly arranged, and parallel to each other, and the grid plane formed by the rows of bars is flat.

The working net is made of stainless steel wire weaving and mainly intercepts slag and other materials.

Gate Slot

The gate slot is made of steel plate folded into a "[" shape, with certain strength and rigidity, ensuring that it does not deform during use.

2. Working Principle

Flat bar screens are used at the water intake of waterworks to intercept larger floating objects and protect the normal operation of subsequent treatment structures.

Product Consulting

We will contact you within one working day. Please pay attention to your email.