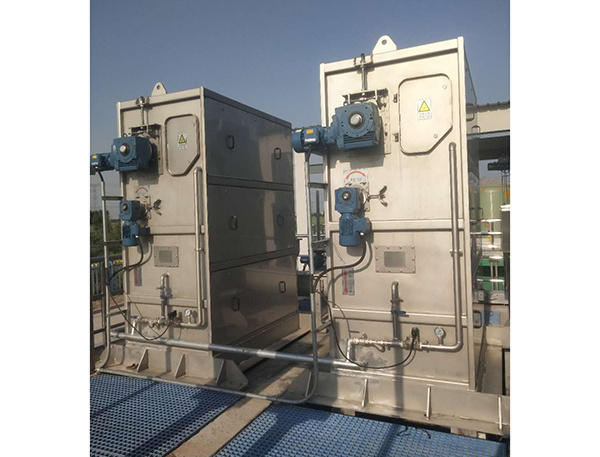

XKBG type inner flow fine screen bar screen cleaner

Keywords: pretreatment equipment, aeration equipment

Product Description

The XKBG type inward-flow fine (membrane) screen cleaning machine is placed after the coarse screen cleaning machine at the inlet of the wastewater treatment plant or directly in the front channel of the MBR membrane treatment, removing various solid particles, floating objects, hair fibers, etc., to ensure the normal operation of subsequent equipment. It is mainly used in wastewater pretreatment or MBR membrane treatment processes.

Features:

● The closed-loop traction chain and the guide rails on both sides of the equipment form a closed transmission chain, which can prevent debris from entering and jamming the traction chain, ensuring stable and reliable operation.

● The equipment above the channel is completely enclosed with an outer casing, and has a removable inspection cover for easy collection of odor.

● Simple operation, low failure rate, significantly reduced wearing parts compared to rake screen, and long service life.

● Thorough and clean slag removal, no winding phenomenon, thus greatly improving filtration efficiency.

● Stable operation, low noise; light rotating parts, low energy consumption.

● Simple structure, convenient installation and maintenance.

Working principle

Inward-flow fine (membrane) screen cleaning machine, wastewater enters from the middle of the perforated fine screen, and is discharged from the inside to the outside through the perforated screen plates on both sides, and the garbage is intercepted by the screen plate. When the water level rises to the set level, the screen plate drive motor works, and the intercepted screen residue is lifted to the upper slag discharge area along with the perforated screen plate. The screen residue falls into the screen residue tank under the combined action of its own weight, cleaning brush, and pressure flushing water. It is then transported to a high-drainage press by a chute or conveyor for transportation, dehydration, and pressing. The screen plate is also cleaned at the same time and enters the next work cycle.

The cleaning brush is set at the starting point of the screen mesh return, driven by a separate reduction motor. While the filter mesh is moving, it assists in unloading and cleaning the outer surface of the screen plate. The cleaning brush bristles are made of nylon material.

If there are still contaminants adhering to the screen plate after unloading, they will be washed away by the pressure water sprayed from the washing device set between the front and rear filter meshes, thoroughly eliminating the blockage of the screen holes.

Product Consulting

We will contact you within one working day. Please pay attention to your email.