XZBG, XNBS, and XNG peripheral drive sludge scrapers and thickeners

Keywords: pretreatment equipment, aeration equipment

Product Description

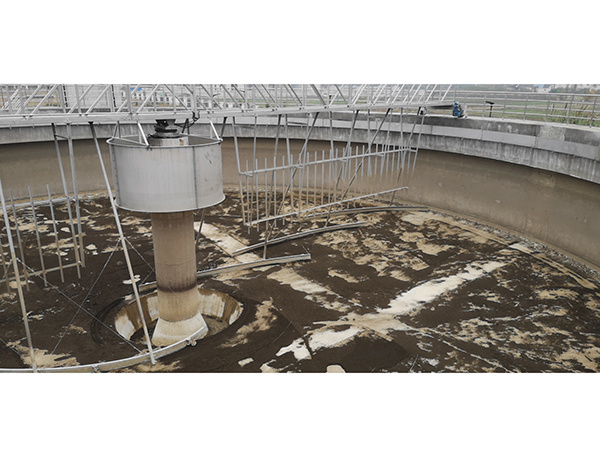

XZNBS Peripheral Drive Sludge Scraper and Thickener

The XZNBS peripheral drive thickener is mainly used in the thickening sedimentation tanks of large wastewater treatment plants (generally with a water volume greater than 600m3/h and a tank diameter greater than 20m) to scrape and collect the settled sludge in the tank. A scum and foam scraping device is usually also installed on the water surface.

The treatment process is generally central inflow, peripheral outflow, and central sludge discharge.

A central column, which also serves as an inflow pipe, is generally installed in the center of the tank. The lower part of the column is connected to the tank's inflow pipe, while the upper opening is sealed to serve as a platform for the central support, with water outlets around the pipe wall. The central column is mostly made of reinforced concrete, but steel structures can also be used.

Its characteristics

Uses a hinged scraper arm to provide overload protection and effectively reduce investment costs;

The working bridge uses a truss beam, which is lightweight, has good rigidity, and the bridge length can be customized according to different process and site requirements;

The sludge scraper plates are arranged in a paired spiral pattern to improve sludge scraping efficiency, and rollers are installed at the bottom to effectively prevent jamming;

Scrapes sludge layer by layer during operation, ensuring a clean and thorough process.

Working principle

Wastewater enters the sedimentation tank through a central calming tube at a certain flow rate. As the flow rate decreases, the inert and active sludge in the wastewater settles to the bottom of the tank. The thickener drive mechanism drives the working bridge to rotate along the tank plane. The working bridge drives the scraper arm to rotate, and the scraper plates fixed to the scraper arm gradually scrape the settled sludge from the edge of the tank to the central sludge hopper. The thickening bars installed on the scraper arm rotate accordingly, accelerating sludge settlement. The sludge is discharged from the tank under its own water pressure (or water pump). The floating scum on the water surface is collected by a scum removal device installed at the water level of the thickener and discharged into a scum hopper. The clear water at the top flows over the scum baffle and into the next process through the effluent weir, removing the settled sludge and scum from the wastewater.

Product Consulting

We will contact you within one working day. Please pay attention to your email.