XHJX type gantry crane sludge suction machine

Keywords: pretreatment equipment, aeration equipment

Product Description

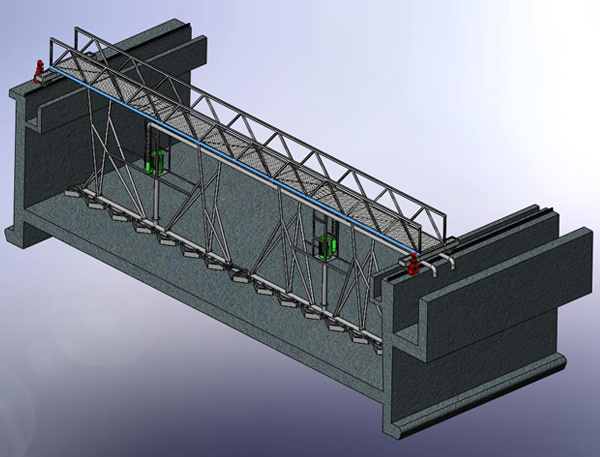

XHJX Gantry-type Sludge Suction Machine

XHJX Gantry-type Sludge Suction Machines are commonly used in horizontal flow sedimentation tanks for wastewater treatment and water supply and drainage projects. Water enters through a multi-porous wall at one end and exits through a collecting tank at the other. The sludge suction machine moves back and forth in the horizontal flow tank to remove sludge from the bottom. Compared to other sludge suction machines, its advantage is that the sludge being removed (fine particles, difficult to settle) does not disturb the water body, but the sludge has a higher water content.

The sucked sludge is directly discharged outside the tank, avoiding sludge displacement and reducing sludge interference. Inclined plates or tubes are installed in the upper part of the sedimentation tank, resulting in better sludge sedimentation and clearer water above.

Features:

Uses a sludge pump for suction, providing strong suction and thorough sludge removal;

Smooth operation, no track climbing during long-distance travel;

Expandable functionality, can be made into a pump and siphon dual-use machine, and can be equipped with backwashing or a non-clogging pump to prevent clogging. PLC control can achieve fully automatic operation for the entire or half cycle, and can also be equipped with a turbidity meter for intelligent control;

Particularly effective in removing extremely fine sludge (particles smaller than 0.1mm);

Sludge discharge volume can be adjusted according to user process requirements to save water;

The sludge suction nozzle works with the scraper plate for better sludge removal, effectively removing various sediments from the bottom of the tank.

Working Principle

The pump suction sludge remover generally stops at one end of the sedimentation tank. The submersible pump is started, and after the sludge discharge volume stabilizes, the gantry drive motor is started to move the sludge remover along the track to discharge sludge (towards the other end). When it touches the return trip limit switch, the drive motor stops and then reverses, and the sludge remover begins its return trip. When it reaches the initial position and touches the limit switch, the sludge remover stops, and the submersible pump is turned off, stopping sludge discharge, thus completing one sludge discharge cycle and waiting for the next command.

The above is one sludge discharge cycle. After a set time (0-24 hours), the sludge remover automatically performs a second sludge discharge cycle. The waiting time between each cycle is determined by process requirements.

For conditions with a large amount of sediment at the inlet end of the sedimentation tank and a longer tank length, the operation mode of the sludge remover can be set to first discharge sludge for half a stroke, then a full stroke, followed by a timed waiting operation to meet the sludge discharge process requirements.

Product Consulting

We will contact you within one working day. Please pay attention to your email.