XBJ, XGJ, and XJJ type mechanical accelerated clarification pool mixers and scrapers

Keywords: pretreatment equipment, aeration equipment

Product Description

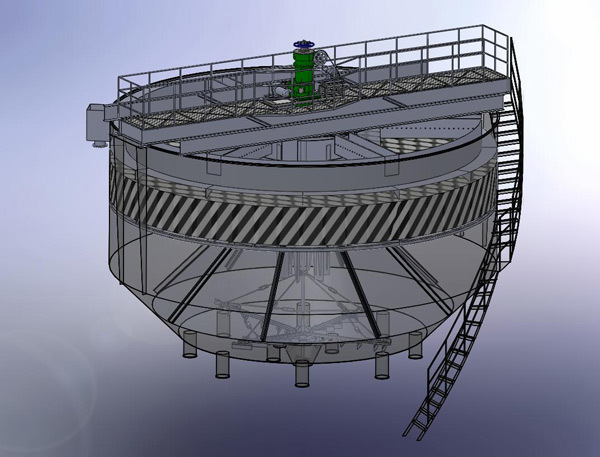

XJJ Type Accelerated Clarifier Mixer Scraper

The mechanical stirring clarifier is a sludge recirculation type pool. The sludge circulating in the raw water is stirred and lifted by the stirring paddle and mechanical impeller, which can fully mix and react with the chemical solution to improve the clarification effect. The entire pool consists of a first reaction chamber, a second reaction chamber, and a mud-water separation chamber. After the mud and water are separated in the separation chamber, part of the settled sludge is discharged periodically from the mud hopper in the separation chamber; another part enters the first reaction chamber through the reflux slot, and the heavier sludge settles at the bottom of the pool, and is scraped and discharged out of the pool by the scraper. The remaining sludge is lifted by the impeller and then recirculated, forming a dynamic balance.

Working Principle

The accelerated clarifier mixer scraper is used for the accelerated clarifier in water supply projects. The raw water mixture that has been added with coagulant and the activated sludge in the clarifier form sludge reflux and contact reaction through the lifting action of the mixer, forming larger flocs, which are then settled and separated by the separation chamber. The remaining sludge is scraped by the scraper to the sludge hopper and discharged by hydrostatic pressure. The clear water at the top is collected and discharged out of the pool by the annular collecting tank installed on the top of the pool, so as to achieve the clarification effect of mud-water separation.

Product Consulting

We will contact you within one working day. Please pay attention to your email.