High-efficiency sedimentation basin

Keywords: pretreatment equipment, aeration equipment

Product Description

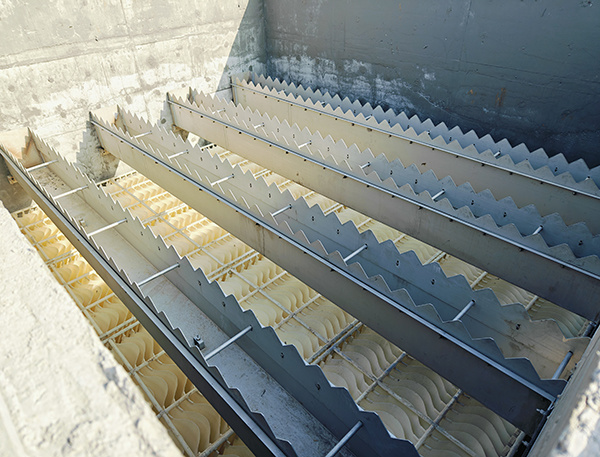

Inclined Plate Settler Technical Description

A high-efficiency inclined plate settler is a technologically advanced solid-liquid separation device. According to the direction of water flow, it is divided into three types: counter-current flow, lateral flow, and co-current flow. The device is equipped with many parallel inclined plates or parallel inclined pipes with small intervals, which improves the sedimentation effect and effluent rate, especially for the removal of dispersed particles.

Features:

1. High efficiency removal effect, thus requiring only about 30% of the area of a conventional sedimentation tank.

2. This equipment is a complete set of equipment, all manufactured in the factory, so installation is simple and can effectively save construction time.

3. Simple maintenance and cleaning.

4. Sludge can automatically fall into the hopper, facilitating sludge discharge and reducing the labor intensity of sludge removal.

Working Principle:

Wastewater enters the tank body through the inlet pipe, flows downward through the inlet chamber located in the middle of the tank body, is reflected by the guide plate, and then enters the inclined plate through the inlet water distribution port inside. As the solution flows upward, the solid particles contained in it settle on the parallel inclined plate components and then slide into the sludge hopper at the bottom of the tank body. In the sludge hopper, the sludge is concentrated and discharged through the sludge outlet. The clarified liquid leaves the inclined plate and flows out through the outlet passage at the top, then flows into the adjustable weir, and flows out through the outlet pipe.

Product Consulting

We will contact you within one working day. Please pay attention to your email.