XDGG type monorail scraper

Keywords: pretreatment equipment, aeration equipment

Product Description

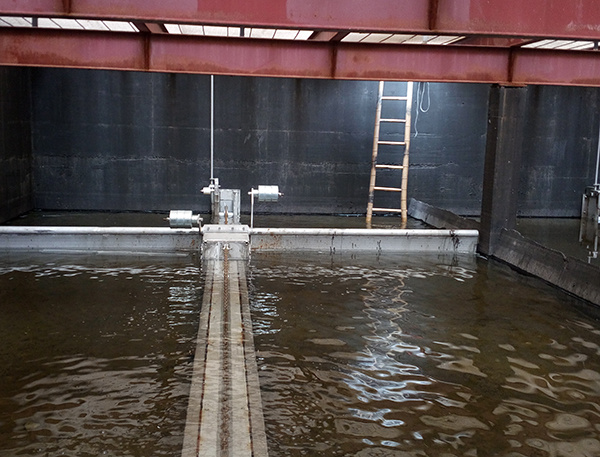

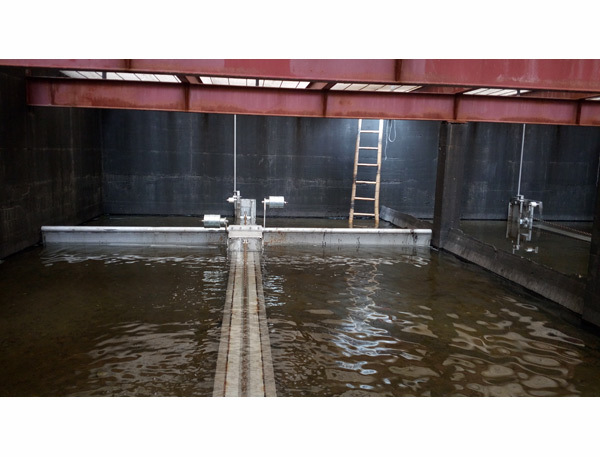

XDGG Type Single-Track Sludge Scraper

The XDGG type single-track sludge scraper is suitable for sludge discharge in facilities such as large waterworks horizontal flow sedimentation tanks. It not only saves land and improves water quality but also achieves energy saving and emission reduction. It is equipment that scrapes sludge from the bottom of the horizontal flow tank from the outlet area towards the inlet area, finally scraping it into the sludge sump in the inlet area for centralized discharge.

Its characteristics:

Energy saving and emission reduction;

Land saving;

Improves the water quality of the sedimentation water;

Used for the renovation of old water plants, it can increase the water production by about 50%.

Working principle

The underwater sludge scraper is installed at the bottom of the horizontal flow sedimentation tank. A track of equal length to the sedimentation tank is laid longitudinally in the middle of the bottom of the tank. Two wing scrapers are installed on a carriage running on the track. It is driven by a central drive device at the top of the tank pulling a circular chain. The circular chain drags the carriage (scraper) along the track forward or backward. When the sludge scraper moves, the scraper stands upright and perpendicular to the bottom of the tank, scraping the sludge at the bottom of the tank towards the sludge sump for centralized discharge; when it retreats (returns), the scraper is flipped and runs parallel to the bottom of the tank. The edges of the scraper that contact the bottom and sides of the tank are rubber plates to ensure that there is a relatively small gap or slight soft contact between the scraper and the tank wall during scraping.

Product Consulting

We will contact you within one working day. Please pay attention to your email.